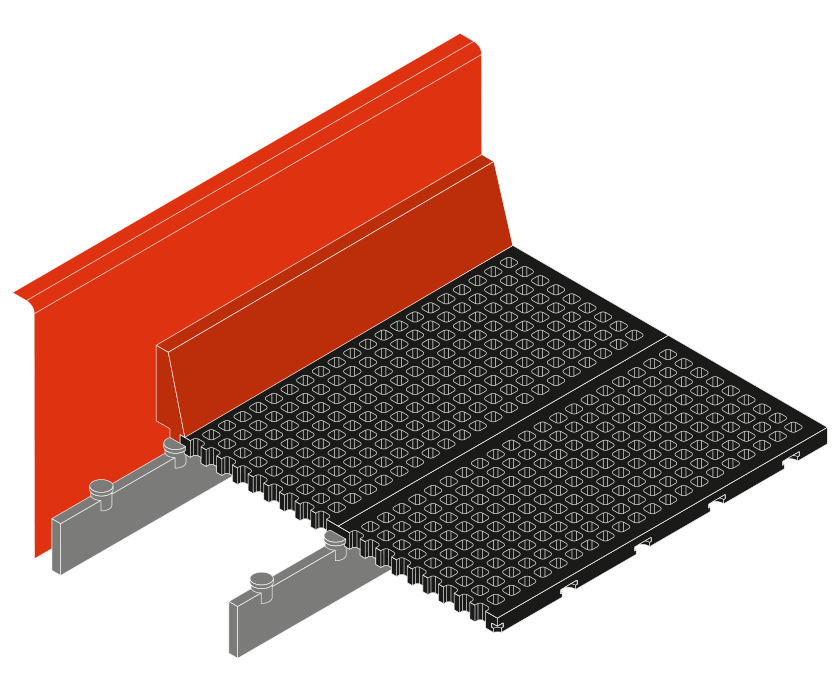

Bolts are evenly distributed along upright flat bars and secure the standardised screen elements. There are no additional attachment parts required: the bolts are simply hammered in for assembly or levered out for removal.

Advantage

Advantage

Easy to assemble

Advantage

Advantage

Variable

Depending on the field of application, screen panels made from KÜPRENE, GK-SOFT, GIGANT or CLEAN are used. These panels are often affixed to the steel construction without any additional attachment parts or strips. This also means a variety of materials can be used on the screen deck.

Materials

GIGANT

Vulcanised rubber with a hardness of approx. 60 Shore A. Very resistant to abrasion and elastic.

KÜPRENE

Wear-resistant polyurethane with a hardness of 90 Shore A. Elastic and impact-resistant. Resistant to water and many chemicals.

CLEAN

Vulcanised rubber with a hardness of approx. 35 Shore A. Extremely flexible and wear-resistant.

GK-SOFT

Polyurethane in various degrees of hardness up to 85 Shore A. Wear-resistant and elastic.

Areas of application/Applications

Special properties

Optimum use of the perforated base with various screen panels

Technology

Patented steel substructure

Product advantages

Largest possible open screen area

Maximum screening performance

Easy to assemble

No additional attachment parts required

Various materials on a screen deck possible

Suitable for original equipment and retrofits

Very efficient